Automation

Automation

Diversified's RoboLogger™️ is the industry's only fully-automated sample collection device, which catches and analyzes samples with greater fidelity and allows for better geological understanding — directly translating into returns on investment almost immediately. Across entire wells or fields, Diversified's automation solutions provide unmatched geological certainty and completion optimization.

RoboLogger™️

The RoboLogger™– is the industry’s only fully automated sample collection device.

It is designed to collect 25 to 30-gram samples at a maximum rate of 2 minutes per sample.

RoboLogger™️ — The Future of Mudlogging

Greater Data Density

Robologger™ increases the data density of cuttings and cuttings related data during the rapid drilling common in unconventional drilling. It collects, cleans and stores faster than can be achieved manually and reduces the human footprint at the wellsite and HSE risks. The Robologger™ works in any weather.

Instant & Remote

Easy to deploy, realtime operation can be controlled remotely and samples can be viewed immediately, directly on the customer’s computer. Human interaction is required to replace the storage reel which can then be analyzed in a wellsite geochem cabin, or in an offsite Diversified laboratory.

Higher Resolution Sampling

With a greater number of samples and our XRF analysis we achieve far higher data resolution which leads to better stratigraphic correlation, improved understanding of geomechanical properties and optimized completions. Wells in a pad or field can be correlated effectively without the need for high-cost and high-risk downhole logging tools or coring runs.

With RoboLogger™️, you'll enjoy:

- High resolution sampling

- Lower HSE risk

- Consistent sampling

- Automated sample images

- Optimized completion designs

- Dispositional environment models

- Lowered costs and risk by replacing those high-risk and high-cost services with automation via RoboLogger's™️ automation capabilities

Automated Collection & Collections Processing

RoboLogger™️ EZ

Robologger™EZ increases the data density of cuttings and cuttings related data during the rapid drilling common in unconventional drilling. It collects, cleans and stores faster than can be achieved manually and reduces the human footprint at the wellsite and HSE risks. Easy to deploy, realtime operation can be controlled remotely and samples can be viewed immediately, directly on the customer’s computer.

With a greater amount of samples and our XRF analysis we achieve far higher data resolution which leads to better stratigraphic correlation, improved understanding of geomechanical properties and optimized completions. Wells in a pad or field can be correlated effectively without the need for high-cost and high-risk downhole logging tools or coring runs.

Sample Collection, Easier Than Ever

RoboLogger™️ EZ

The RoboLogger™️ EZ is the most economical solution in the RoboLogger™️ line, providing complete XRF and geosteering support while fitting into a more compact form-factor. Robologger™️ EZ deploys to the wellsite with a manned on-site crew and comes equipped with a "samples on-demand" feature for quick and easy sample collection. Samples are always at your fingertips, as operators can simply press a button to deliver samples straight to the surface, immediately ready for manual analysis.

Fully Automated Collection & Analysis

RoboLogger™️ X

RoboLogger™ X leads to improved geologic understanding, geomechanical rock properties, stratigraphic correlation, and geopositioning leading to better production. Economically, every well drilled can benefit from high quality FE data from spud to TD without the need for high-cost and high-risk downhole logging tools or coring runs. The Robologger™ X instrument combines the remote sample catching functionality of RoboLogger™ EZ with realtime elemental analysis of cuttings by Elemental Analysis (XRF). The complete redesign of the fluid handling, sample handling, electronics, and measurement zones along with enhanced safety systems has created a portable, functional and serviceable instrument for both on and offshore deployment.

Using Your RoboLogger™️

Installation

RoboLogger™ is installed in a couple of hours with minimal rig Intervention. The process involves the connection of a hydraulic collection device, which is submerged in the possum belly or flow line. The samples are drawn into the machine via specialized pumps and valves, and are deposited in the machine’s collection chamber.

Collection

Solids and liquids are separated by a proprietary extraction system and correlated to lag depth via a Wellsite Information Transfer Standard (WITS) connected to the Electronic Drilling Recorder or other data acquisition system of record. Samples can be manually received or processed through further automation systems.

Operation

A RoboLogger™ was deployed on a core drilling program in West Texas. It was active throughout the well catching 10’ and 20’ samples at the client’s request. The total interval collected was 4718’ including 1150’ during the cored sections. 508 samples with 479 samples 15gms or greater. The system consistently collected at 10’ intervals vs. 30’ from mudloggers. An average ROP of 100’/hr. gave the system10 collections per hour, vs. 3 collections per hour from mudloggers.

Evaluation

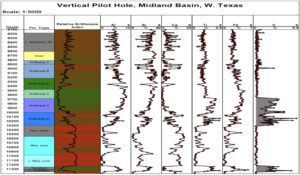

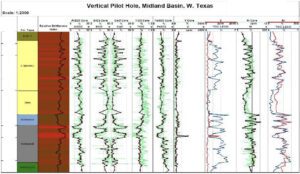

XRF analysis was carried out on the samples, providing important insights into the nature of the elemental and mineralogical composition of the rock (and the cost-effective utility of the RoboLogger™️). Several observations can be drawn from the data. The Redox element vanadium, commonly a proxy for TOC (Total Organic Carbon), can be seen at its highest levels in the Woodford, Wolfcamp D and Wolfcamp D1. The most ductile rock can be seen from the green shading on the relative brittleness index in Wolfcamp C & D. Silica and Calcium trend in opposite directions as sequences change from predominantly siliciclastic to carbonates. See figure 1.

Diversified Well Logging

Diversified Well Logging