When a stereoscopic microscope, tweezers, sample probe, some chemicals, and an ultraviolet lightbox were the ‘state-of-the-art’ in cuttings evaluation equipment, mud-loggers and geologists did a very good job in identifying drilled formations all things considered. Similarly, when coach-and-horses and sailing ships were the ‘state-of-the-art’ in transportation, they also did a very good job transporting people and goods from place to place.

But times change.

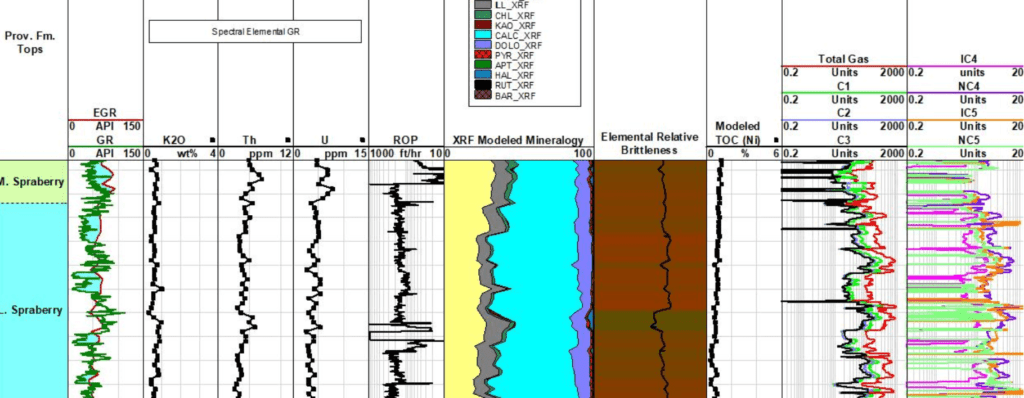

In the mud-logging world, Diversified Well Logging (DWL) is embracing X-Ray Fluorescence as the new ‘normal’ for realtime sample evaluation. Driven in part by the demand for better geological information in unconventional formations that are difficult to impossible to examine accurately under the microscope, elemental analysis can be used to accurately determine the elemental, mineralogical, lithological, and geomechanical properties of a sample. With this quantitative data, we will know exactly what the formation is and where we are in it. No more fifty shades of grey, but a wide range of ‘colorful’ elements.

With what DWL is calling Hybrid Mud Logging, our field geologists will be able to respond to wellbore issues with more certainty. Where answers to downhole questions used to include a ‘maybe’ or a ‘possibly’, we will now have rock solid evidence. For example:

Q1: Why am I now drilling slowly when I am in the same formation? My gamma ray and visual cuttings descriptions are the same. Is the bit or motor failing? Are there hole cleaning issues? Do I really have to waste time and money and trip out of the hole to check?

A1: Realtime geochemical analysis with XRF will help determine the cause. Evidence of biogenic or authigenic silica – siliceous/quartz cement will affect the ROP. Evidence of carbonate cement can also affect the ROP. Subtle changes in the clay type that will lead to swelling can affect the ROP. Or no change in lithology at all would indicate there is a hole cleaning, bit or motor problem. Whatever the answer, there is evidence to back it up.

Q2: I am starting to see an increase in cavings, but where are they coming from? The cuttings seem to be the same. Do the new formations have stability issues? Are the cavings coming from destabilized formations up-hole? Is hole geometry or drill-string configuration involved? Should mud properties be changed?

A2: Hybrid Mud Logging with elemental cuttings analysis can help answer the questions. The elemental signature of the cavings will definitely confirm their origin. The exact zone the cavings are from will determine if hole or pipe geometry is a contributing factor. And a change in mineralogy / clay type of the new formation can indicate a mud property change is needed.

Q3: I am geosteering but now, 750 feet away from TD, my gamma ray tool has failed. Do I trip out of the hole to change the tool and waste time and money? Do I drill ahead blindly, possibly deviate out of the target and maybe lose the footage for production and waste money drilling? Or, shall I call TD short, definitely lose the 750 feet for production, but save the drilling costs?

A3: With Hybrid Mud Logging, the other option would be to Chemosteer the final 750 feet. A trip would be avoided, and the uncertainty surrounding the possible loss of a productive section of hole would be avoided.

These are just three examples of how quantitative elemental analysis of the cuttings can greatly improve the decision-making process and bring value that far outweighs the cost. There are many more. In general, of course, it comes down to operators wishing to improve their returns on investment. Hybrid Mud Logging will do that.

One final example with Hybrid Mud Logging and Chemosteering is estimated to have saved an operator at least $10 million. A third well on a pad intersected an unexpected change in structure above the target, identified with realtime elemental cuttings analysis. Quick interpretation allowed the well-path to be altered and by Chemosteering the reservoir target was successfully intersected. If the change in structure had not been identified, a $10MM sidetrack would have been necessary.

Diversified has embraced the future and is now pioneering its Surface Measurement While Drilling services (Hybrid Mud Logging, Chemosteering, Automated Remote Mudlogging). In short order, we believe that our clients will appreciate the new service benefits as they see their geological knowledge grow along with the profitability of their wells.

Diversified Well Logging

Diversified Well Logging