In a Rigzone article on June 10th, 2020, ConocoPhillips CEO Ryan Lance was quoted as saying “Shale is not broke; shale is not gone; shale will come back.” While the third statement seems to contradict the second, we all know what he means, and we all agree. Shale and other tight unconventional hydrocarbon plays are valuable strategic resources.

Being of strategic value it makes sense that more care should be taken to assess (and indeed access) the real potential of these formations. For years we have all seen similar reports of unconventional wells underproducing, for example, “of the thousands upon thousands of unconventional wells that have been drilled, 70% do not meet their production targets and 30% of all perforation clusters fail to produce.” This was stated back in 2016. I will generously assume that the statistics have improved, but possibly not, which begs the question why?

The first answer that comes to mind is that oil production was good enough to keep investors relatively happy. “Wells drilled in past 2 years provide nearly half of U.S. oil”, was the title of Adam Wilmoth’s piece in ‘The Oklahoman’ from March 27th, 2016. I am not much good at math but if that 50% of U.S. oil was coming from 70% of the formation in only 30% of the wells drilled then the U.S. could probably have been self-sufficient in, and exporting vast quantities of oil and gas way back when. But no, and again, why?

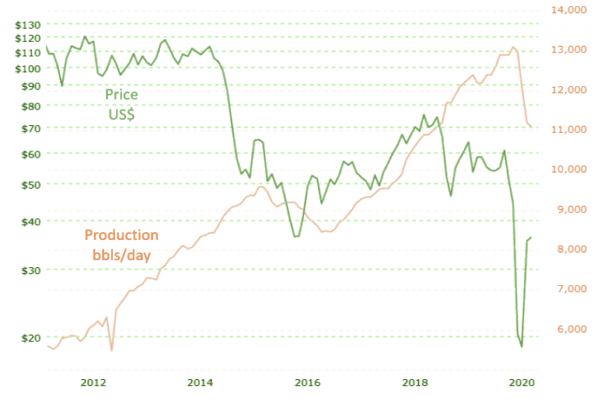

U.S. production vs. price - just missing the sweet spot?

The second answer that comes to mind is that unconventional drilling being a relatively new business did not quite know what it was doing. Conventional formations were easy(ish). Unconventional ones were proving trickier, though the elevated price of oil helped justify drilling more and more. According to data from the ‘Energent, Westwood Global Energy Group’, as quoted in ‘JPT’ from February 2019, around 32,500 unconventional wells were drilled in 2014, which seems to be a rather good number of ‘practice runs’. Early lateral wells were shorter than today’s, so if we estimate each one at an average of 6000 feet, that is an impressive 195 million feet of data available to figure out why only 30% were good and 70% were not. Although I am completely ignoring political and economic factors, it still seems that the 20,000 or so wells drilled and completed in 2019 are far from being capital-efficient monsters of production. Once more, why?

The third answer seems to be a lack of real geologic knowledge. Certainly, we have the 195 million feet of hole drilled in 2014 and as a very, very rough estimate another 702 million to the end of 2019. Even the biggest big-data fan cannot complain about those numbers. But is the data available for study? Probably not. Due to the pressure to produce hydrocarbons and get a reasonable return on investment the focus seems to have been on capital-efficiency, that is, once pilot holes were drilled and evaluated with cores, downhole LWD tools, and wireline logs, the big money had been spent with lateral targets being simply drilled as best they could with gamma ray for geosteering and cuttings descriptions and gas for the geology.

There goes your big-data.

In conventional drilling environments, drilled cuttings and gas are of great use when observing changes in formation. In conventional drilling the reservoirs are generally distinct from the formations that surround them. However, the unconventional environment is not that simple even though it may appear to be – find the right formation and drill sideways through it as far as you can go. The trouble is, unconventional formations are not the homogenous things they are thought to be. There are facies changes, isolated influxes of debris, differences in diagenesis or localized chemistry, and of course fracturing and faulting that may or may not be visible prior to drilling. When relying on the observation of cuttings to give you the best hydrocarbon potential and production information on these complex rocks, you are probably going to be disappointed. This means the 70% under-productive figure, and 30% fracture cluster failures for unconventional wells should come as no real surprise. The need for speed (and economy) has turned our valuable strategic resource into more of a drain on capital.

With cost reductions and capital efficiency and return on investment still uppermost in everyone’s minds it would appear that the possibility of getting better in-depth geological data necessary to turn unconventional drilling into a win-win every time would be slim. But no. There are solutions and economical ones at that.

Diversified Well Logging is fully invested in providing the services to provide more data, better data, and at a price that would allow any company to run those services on every well drilled. And the cost? On many wells, the service pays for itself many times over. Using elemental data from wellsite XRF analysis of cuttings, gas data, drilling data, and, for deeper analysis, advanced A.I. software we combine everything to give surface measurement while drilling solutions that match downhole MWD/LWD results. This means that the geological data that has thus far been largely missing from the roughly 900 million feet of rock drilled since 2014 can start to be collected. Again, imagine the insights that the big-data folk could get from all of this. Could we finally see every well and every fracture cluster producing as expected and hoped for? Geology is geology so maybe not, but we would surely get close and our valuable strategic resource would REALLY be valuable.

Cuttings to completions - value added and cost reduced.

Finally, even on the small scale that Surface Measurement While Drilling is being used by Diversified Well Logging currently, the financial benefits are demonstrable. Using elemental analysis – chemostratigraphy – DWL has successfully steered through faults to pick up the target zone allowing extra formation to be opened for production and adding value. We have also called a stop to drilling after faulting completely out of zone with no way back and saving money. Elemental data has also picked rate-of-penetration sweet spots allowing faster drilling and saving bits and bit trips that were previously common-place. We have also saved trips for MWD failure by drilling to the planned section TD by using calculated elemental gamma ray – this latter cost saving benefit has also been applied in the Gulf of Mexico with even greater savings on unplanned trips. And of course, there is the value of knowledge. Knowledge that can increase profits even in more difficult times.

As we pass a billion feet of unconventional rock drilled has DWL found the magic formula? Possibly not magic, but an innovative and expertly implemented formula certainly and one that will help maintain a profitably healthy industry by treating its valuable strategic resource with the respect it deserves.

Contact DWL for more information on Surface Measurement While Drilling™

Diversified Well Logging

Diversified Well Logging